Target: Concept

Design and improvement: Prototype

Verification: Mass production

-

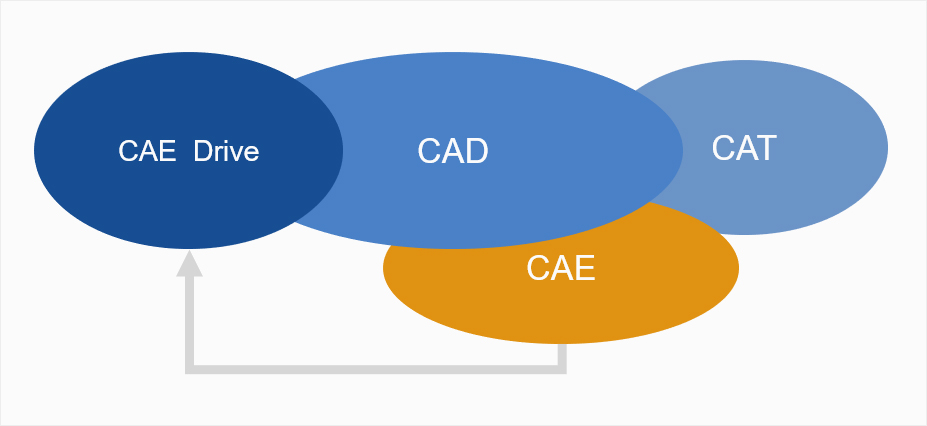

CAD (Catia)

-

3D tolerance analysis

The 3D tolerance analysis tool 3DCS is integrated into catia V5,3D data created by catia can be easily used And define GD & T according to the drawings.

-

Artificial feel analyze – FS characteristics

The artificial feel analysis tool RECURDYN which can simulate the FS characteristics according to the 3D data

-

CAN / LIN bus tool

-

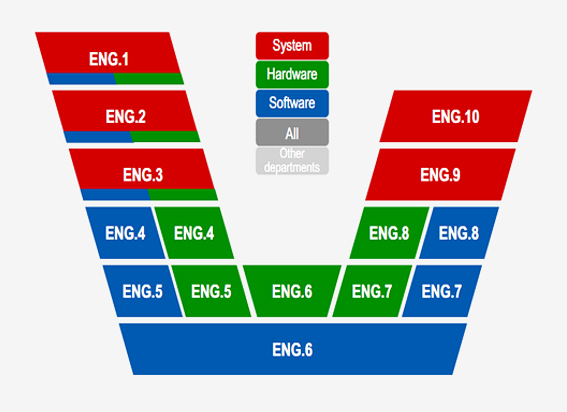

ENG.01:Customer demand export

ENG.02:Customer needs analysis

ENG.03:system structure

ENG.04:Software requirements analysis, hardware requirements analysis

ENG.05:Software design, hardware design

ENG.06:Software coding, hardware circuit board layout

ENG.07:Software module test, hardware module test

ENG.08:Software integration test, hardware integration test

ENG.09:System integration test

ENG.10:System test

-

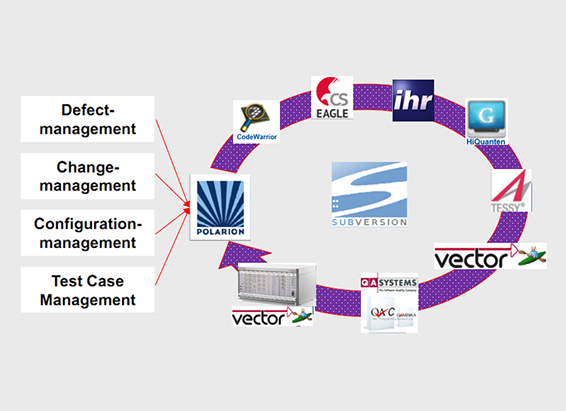

Electronic Development Capabilities

1. Function / performance test

2. Electrical test: a. Long-term overvoltage b. Transient overvoltage c. Transient undervoltage d. Jump start e. Load dump f. Superimposed alternating voltage . . . s. Ground offset t. Overcurrent

3. Climate test

4. Luminance/Color coordinates/Color temperature Test

5. EMC/ESD Test

6. CAN bus conformance test

7. System diagnostic test

8. System boot loading test